The JBZ-S paper cup machine is a highly automated system designed to produce one or two side film-coated paper cups with ease. These cups can be used to hold both hot and cold beverages, making them ideal for soft drinks, coffee, tea, and much more.

Equipped with an ultrasonic sealing system, this machine offers a sound welding effect, which not only saves energy but also improves efficiency. The JBZ-S paper cup machine is designed with a working station that performs all necessary cup-making steps, including automatic paper feeding, ultrasonic welding, oiling, bottom punching, heating, knurling, curling, and cup discharge.

Overall, this machine is perfect for businesses looking to create high-quality paper cups that are both efficient and reliable. With its advanced features and automation capabilities, the JBZ-S paper cup machine is sure to meet all your paper cup production needs.

Main Characteristics

By automatically conducting a multi-position inspection, the alarming system is able to promptly detect any issues and raise an alarm. The system is designed to test and identify problems, and it will sound an alarm whenever any abnormalities are detected.

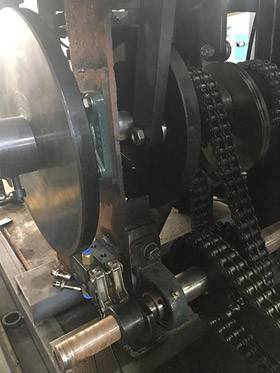

The stable running of the system is guaranteed by the presence of a gearbox and chain transmission system that is characterized by its strength, firmness, and precision.

To ensure a stable operation, our product is equipped with two high quality springs and three strong shafts. These components work together seamlessly to provide optimal functionality and performance.

To ensure the safety of the paper cups during the manufacturing process, our machine is equipped with a high-position stopping device. This allows the machine to always stop at the highest point, ensuring that the mold and the heating furnace are completely separate and the paper cups are protected from being burned. We understand the importance of producing high-quality paper cups that are safe for both the user and the environment, and our machine helps us achieve this.

When it comes to forming cups, a retractable knife is the go-to tool for achieving a consistent bottom and secure seal that minimizes the risk of leaking.

By rearranging the information from the original text, a highly similar content can be generated as follows: The bottom rolling device, which is protected by a patent, offers an embossing force that is five times more powerful compared to traditional rolling devices.

The machine body is clean and easy to maintain.

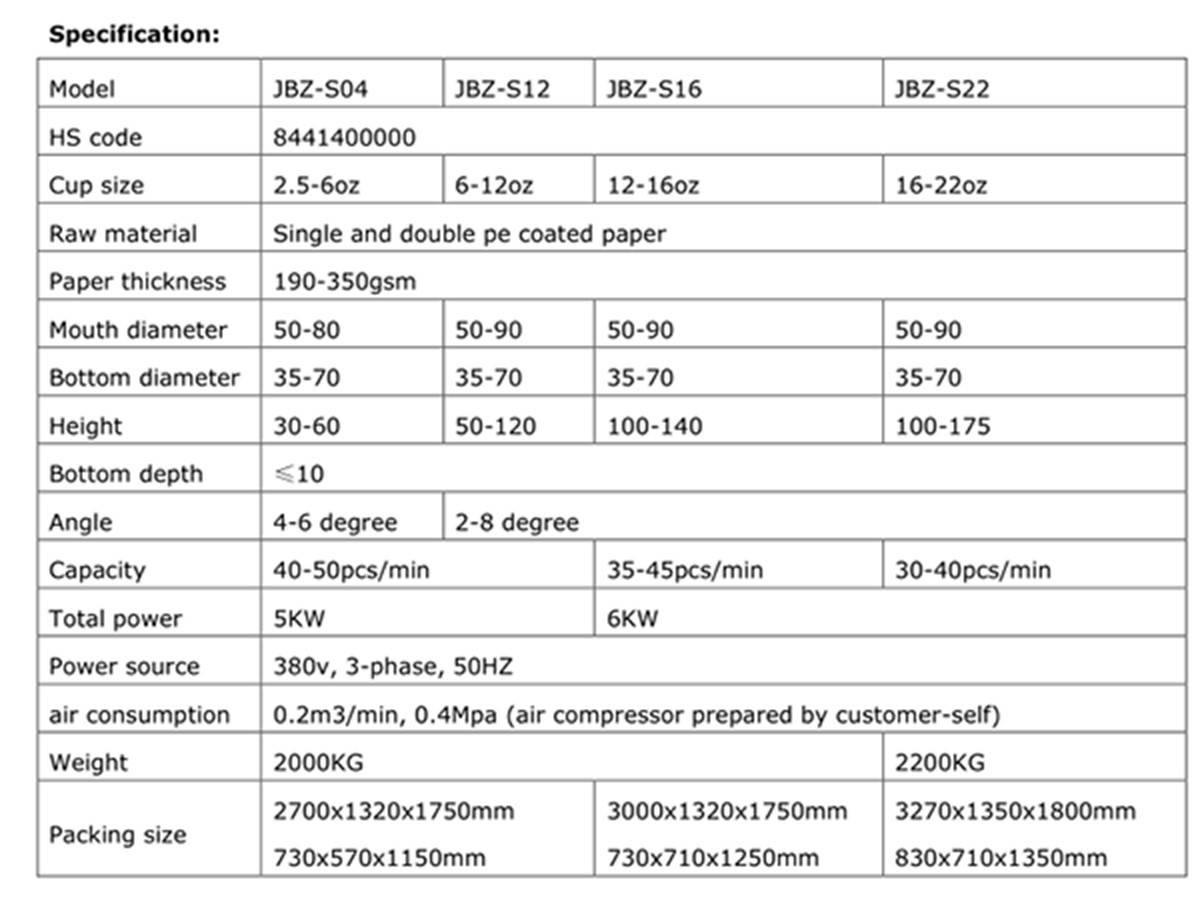

Technical Parameters

|

Model |

JBZ-S04 |

JBZ-S12 |

JBZ-S16 |

JBZ-S22 |

JBZ-S22 (supper size) |

|

Specification of paper cup |

2~6.5OZ |

6~12OZ |

12~16OZ |

16~22OZ |

22-36oz |

|

Paper material |

Single-sided, double-sided PE coated paper |

||||

|

Mouth diameter |

50-80 |

50-95 |

50-95 |

50-95 |

90-120 |

|

Bottom diameter |

35-70 |

35-70 |

35-70 |

35-70 |

70-90 |

|

Cup height |

30-60 |

50-120 |

100-150 |

100-175 |

120-190 |

|

Bottom depth |

≤10 |

≤10 |

≤10 |

≤12 |

≤12 |

|

Angle |

4-6o |

2-8o |

2-8o |

2-8o |

2-8o |

|

Rated productivity |

40-50pcs/min |

35-45pcs/min |

30-40pcs/min |

25-35pcs/min |

|

|

Power supply |

380V 50Hz |

||||

|

Total power |

5KW |

6KW |

7KW |

||

|

Weight |

1600Kg |

1900Kg |

2000KG |

||

|

Packing size(L*W*H) |

2800×1350×18000mm |

2800×1350×18000mm |

3000×1450×1900mm |

3300×1450×2000mm |

3300×1450×2000mm |

Sini is a China paper cup machine manufacturer and supplier. We offer paper cup machine, and paper cup handle machine, paper plate forming machine, automatic plastic thermoforming machine, paper bowl forming machine. Our high quality products are offered at competitive prices. Sini is located in China, and the full chain of manufacturing paper cup sleeve machine, cake tray forming machine can be completed in China, even in one city. Lower manufacturing cost saves your purchasing cost. The more details of each product are shown on the page with description.

Product

Hot Tags: gear box paper cup machine, China gear box paper cup machine manufacturers, suppliers, factory