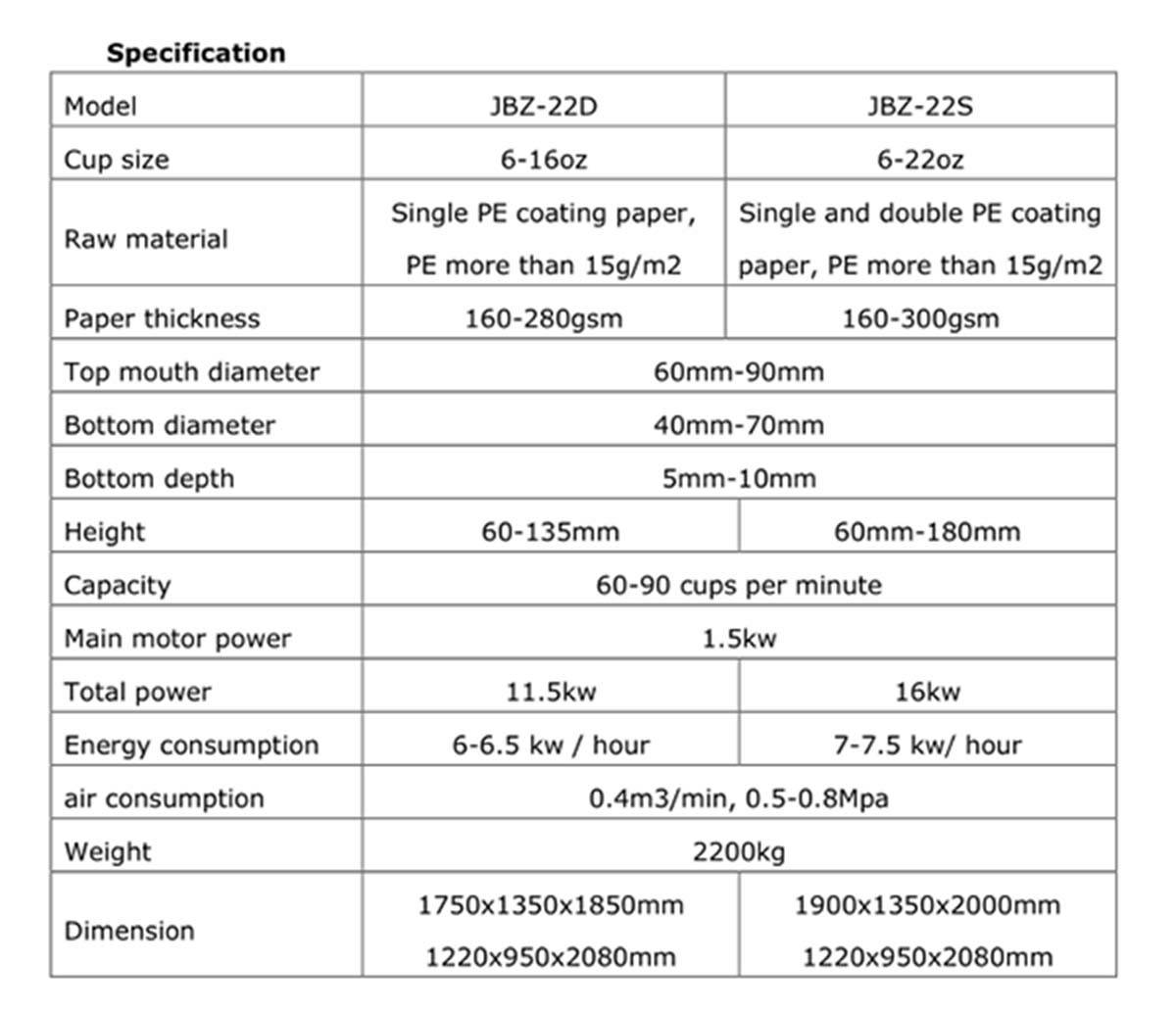

Introducing the cutting-edge Medium-Speed Single Plate Paper Cup Machine, which is a revolutionary product in paper cup manufacturing. This machine outshines its competitors with its top-of-the-line features that include an open-architecture cam drive, an uninterrupted overall spraying lubrication system, an integrated leaf frame, a PLC control system, a triple-hole mechanical arm, low power consumption, energy efficiency, and a compact footprint.

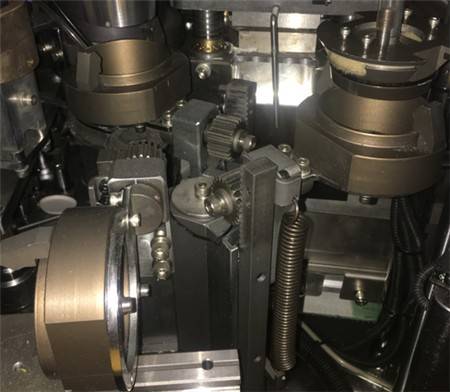

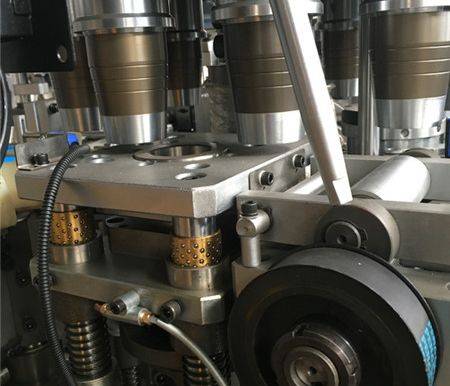

With its open-architecture cam drive, this paper cup machine ensures smooth and precise operation, making it a reliable choice for all your paper cup manufacturing needs. The uninterrupted overall spraying lubrication system ensures that the machine remains well-oiled and in perfect working condition for extended periods.

The integrated leaf frame is a standout feature of this machine, which ensures that there are no complications during the paper cup forming process. The PLC control system offers a user-friendly interface that ensures ease of operation for all operators. The triple-hole mechanical arm provides high-speed paper cup forming, while the economical power consumption of the machine ensures optimum energy efficiency throughout its working cycle.

Lastly, this machine occupies minimal floor space, perfect for businesses with limited floor space. Therefore, if you want to streamline your paper cup manufacturing process, the Medium-Speed Single Plate Paper Cup Machine offers an excellent solution.

The open-architecture cam drive technology is a distinguishing characteristic that enhances the dependability and reduces the need for frequent maintenance of the machine. By implementing this advanced technology, the gears within the machine have undergone optimization to generate efficient and effective movement while consuming minimal energy. Consequently, this boosts the longevity and durability of the machine, making it more resilient and long-lasting in the long run.

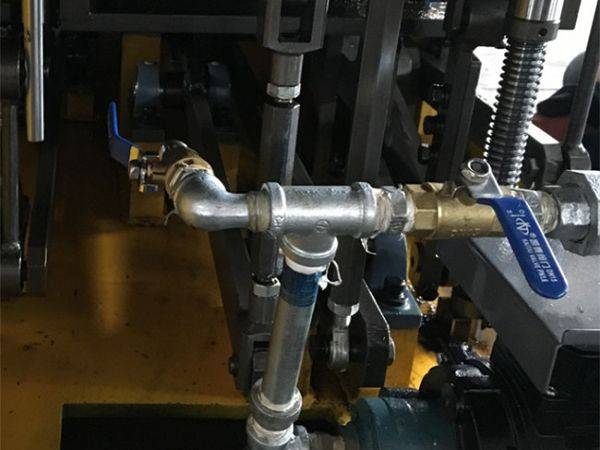

One of the major benefits of the Mid-Speed Single Disc Paper Cup Machine is its continuous and comprehensive spray lubrication system. This advanced feature eliminates the need for manual lubrication, greatly reducing the risk of machine failure and downtime. With this system in place, productivity is increased and the overall efficiency of the machine is greatly improved. Moreover, this lubrication system ensures that the machine operates smoothly and consistently, resulting in a high-quality end product every time. Overall, the uninterrupted spraying lubrication system is a key advantage of the Mid-Speed Single Disc Paper Cup Machine and sets it apart from other paper cup machines in the market.

The maintenance of the cup production machine has been made more efficient and less time-consuming with the integration of the leaf frame which is easily accessible and replaceable. Moreover, the machine is equipped with a state-of-the-art PLC control system that guarantees consistent and precise cup production. With remote control capabilities and real-time monitoring of the production process, the user can easily keep track of the machine's performance.

The mechanical arm with three holes is an advanced pick-and-place system, ideal for businesses that manufacture paper cups. It is designed to handle three cups at once, providing excellent efficiency and productivity. The machine is energy-efficient and consumes minimal power, making it a cost-effective and eco-friendly option. Moreover, it occupies a small floor space, making it a perfect choice for manufacturing facilities with limited space. Overall, the triple-hole mechanical arm is an excellent investment for any paper cup manufacturing business looking to boost productivity and reduce costs in the long term.

The Mid-Speed Single Disc Paper Cup Machine is an innovative and advanced manufacturing technology that excels in efficiency, reliability, and cost-effectiveness. It presents an excellent opportunity for businesses aiming to enhance their paper cup manufacturing process and capitalize on their productivity. By optimizing production and streamlining operations, it proves to be an ideal solution for companies seeking to boost their overall efficiency and profitability.

Advantages

Our cam transmission system boasts an innovative hanging cam design that effectively minimizes pollution. Moreover, it features an open structure that ensures optimal performance.

An automatic lubrication system can be a lifesaver in terms of saving time and effort when it comes to maintenance work. By opting for this system, you can easily eliminate the need for manual lubrication, which can be a very tedious and time-consuming task. With this system in place, you can focus on other important tasks rather than wasting your time and energy applying lubricants to various parts of your equipment. Overall, an automatic lubrication system is the way to go if you want to make your daily work much easier and more efficient.

The Aluminum Mold offers a longer lifespan and is highly resistant to abrasion.

4. Ultrasonic unit guarantee fast and good quality sealing.

5. Unique robot hand design. Make sure no transformer of cup body.

6. Circulatory silicon oil lubrication system. Save the usage of silicon oil and keep machine and cups clean.

7. Bottom paper feeding uses servo motor.

8. Using two heaters to heat up the bottom, ensure the bottom sealing and guarantee high speed production.

9. PLC control system

Product

Hot Tags: high speed open cam paper cup machine, China high speed open cam paper cup machine manufacturers, suppliers, factory