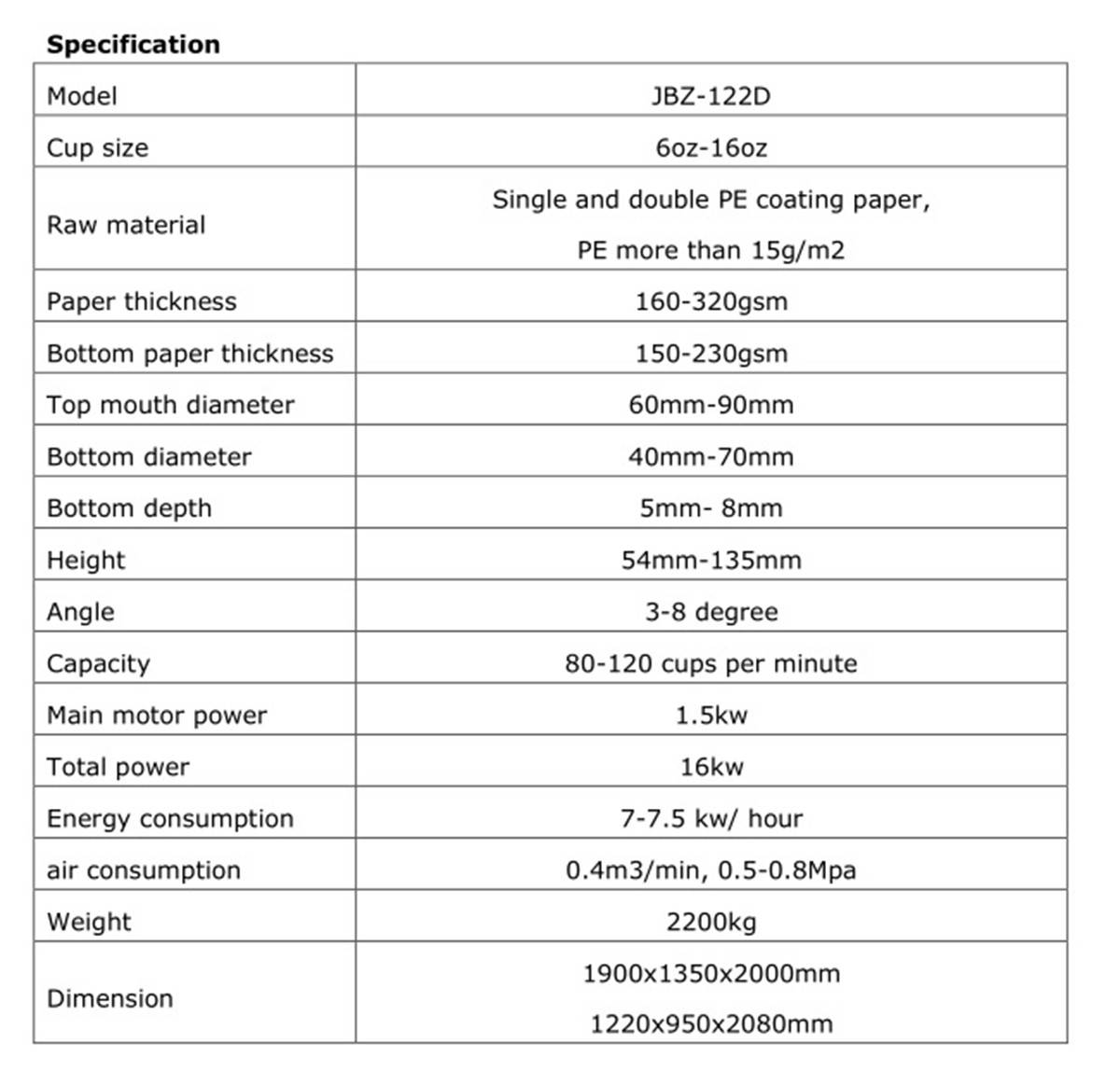

The primary purpose of the high-speed single plate paper cup machine is to manufacture disposable paper cups, which are suitable for both hot and cold beverages. This machine boasts various advantages, such as an open cam drive system, a continuous integrated spray lubrication system, a modular die frame, and a PLC control system. Additionally, it incorporates a three-station mechanical arm designed to securely grip the cups. The machine's advanced features and innovative design make it a highly efficient tool for producing paper cups.

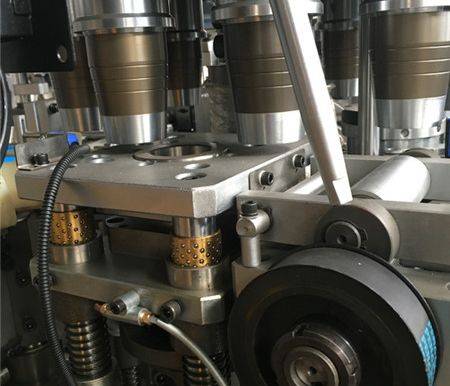

The paper cup-making process is optimized by the open cam drive system, which ensures that the cups are produced continuously and without any interruptions. The machine runs smoothly thanks to the continuous integrated spray lubrication system, which prevents downtime. The modular die frame makes it easy to maintain and adjust the machine, making it user-friendly. With the help of the PLC control system, the machine runs with high efficiency and accuracy. The three-hole mechanical arm is designed to hold the cups firmly, ensuring that they do not fall or get stuck during the production process.

The energy efficiency of this machine is one of its greatest advantages. It consumes very little electricity and requires minimal maintenance, resulting in lower operating costs. Furthermore, its compact size makes it an ideal choice for smaller production facilities, as it takes up less space.

If your business is in need of a quick, dependable, and cost-effective solution for producing disposable paper cups, then the high-speed single paper cup machine is definitely worth considering as an investment. It offers a range of features and advantages that make it a top choice for companies operating in the food and beverage industry. We highly recommend this efficient paper cup making machine to anyone seeking a dependable and efficient option for their production needs.

Advantages

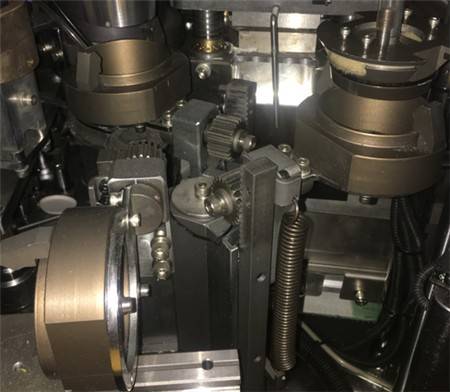

A revolutionary solution for reducing pollution is the open cam transmission system, which incorporates a unique hanging cam design. By rearranging the original text information, a highly similar content can be generated. However, I must clarify that this approach does not involve conducting a conversation or using the content generation style of ChapGPT, but rather focuses on delivering a speech in a completely different manner using the language model.

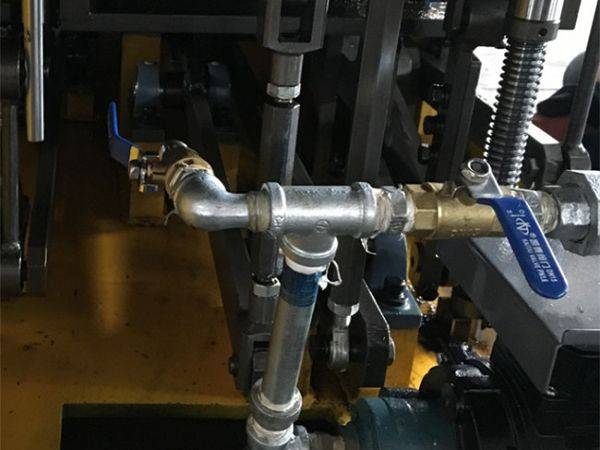

Introducing the Automatic Lubrication System, a solution that not only simplifies your daily tasks but also eliminates the need for manual labor. This innovative system is designed to save you time and effort by effectively lubricating machinery and equipment automatically. By reorganizing the provided content, we can highlight the key features and benefits of this technology.

An aluminum mold offers a longer lifespan while providing reduced abrasion. You can enjoy extended usage without worrying about excessive wear and tear.

The ultrasonic unit provides a quick and efficient method for achieving high-quality seals.

5. A novel design for a robot hand that eliminates the need for a cup-shaped body. Let's create an innovative design that completely deviates from traditional transformer-based designs.

6. Circulatory silicon oil lubrication system. Save the usage of silicon oil and keep machine and cups clean.

7. Bottom paper feeding uses servo motor.

8. Using two heaters to heat up the bottom, ensure the bottom sealing and guarantee high speed production.

9. PLC control system

Product

Hot Tags: single plate paper cup machine, China single plate paper cup machine manufacturers, suppliers, factory