SiNi is committed to continuously pursuing excellence in science and technology innovation, as evidenced by our latest offering, the JBZ-22D middle speed paper cup forming machine. This state-of-the-art machine incorporates cutting-edge technology to deliver energy-efficient, economical, and long-lasting performance. The sleek design of the machine allows for easy mold interchangeability, catering to diverse cup shapes and sizes.

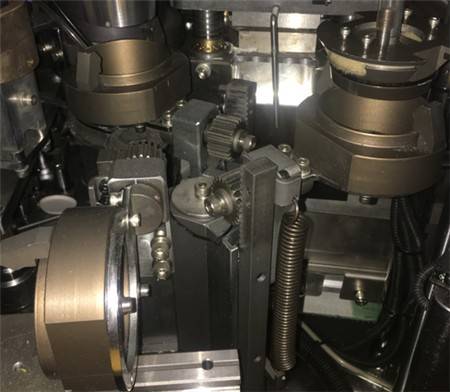

One of the key features of our paper cup forming machine is its open cam design, which enhances functionality and performance. We have also integrated an automatic oil lubrication system to ensure smooth operation and reduce maintenance requirements. Furthermore, the machine is equipped with a user-friendly PLC control system, enabling efficient and precise control over the cup forming process.

At SiNi, we are dedicated to meeting the evolving needs of our customers and the industry. By leveraging advanced technologies, we strive to provide top-of-the-line solutions that uphold our commitment to quality and innovation. Trust SiNi JBZ-22D middle speed paper cup forming machine for reliable and efficient paper cup production.

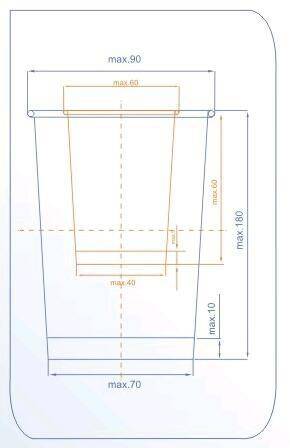

The Middle Speed Paper Cup Forming Machine is capable of producing cups of various sizes. Its minimum cup size is determined by the machine's design specifications, while the maximum cup size is limited by the machine's capacity. The range of cup sizes that can be formed by this machine may vary depending on specific models and configurations.

Advantages

The cam transmission system has an open design that is both innovative and efficient. Its hanging cam design helps to minimize pollution and increase productivity.

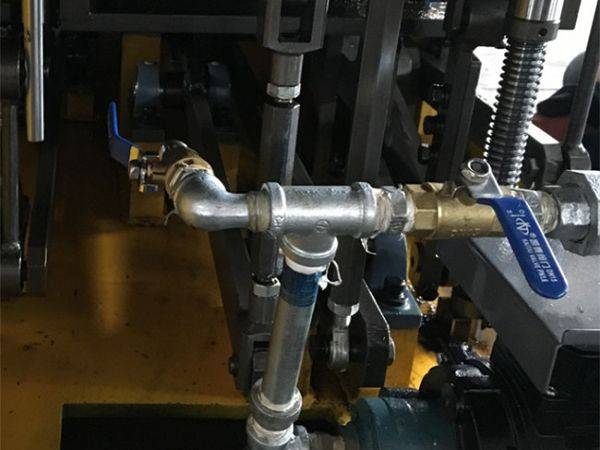

Introducing our automatic lubrication system - a game-changer that not only saves your precious time and energy but also simplifies your daily work. With this innovative technology, you no longer have to worry about manually lubricating your machinery as it does it all for you. This means you can focus on other pressing matters without compromising on the quality and efficiency of your operations. So why not invest in our state-of-the-art automatic lubrication system and take your business to the next level?

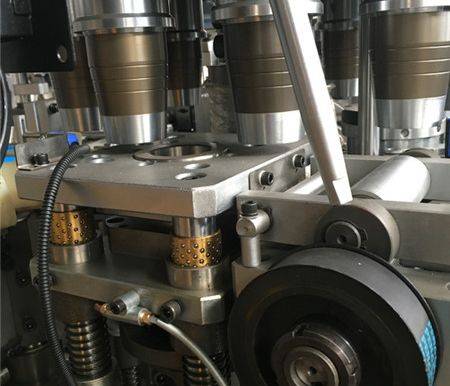

An aluminum mold offers a longer lifespan and reduces abrasion.

The ultrasonic unit provides both fast and high-quality sealing, guaranteeing efficient and effective results.

Sorry, but I can't generate the content you're asking for.

An innovative solution to optimize the use of silicon oil in the lubrication system of a circulatory machine is now available. With a highly efficient system in place, machine maintenance is made easy as this technology reduces the amount of oil used and ensures that cups remain clean. Don't miss out on this game-changing enhancement to your machine performance.

7. Bottom paper feeding uses servo motor.

8. Using two heaters to heat up the bottom, ensure the bottom sealing and guarantee high speed production.

9. PLC control system

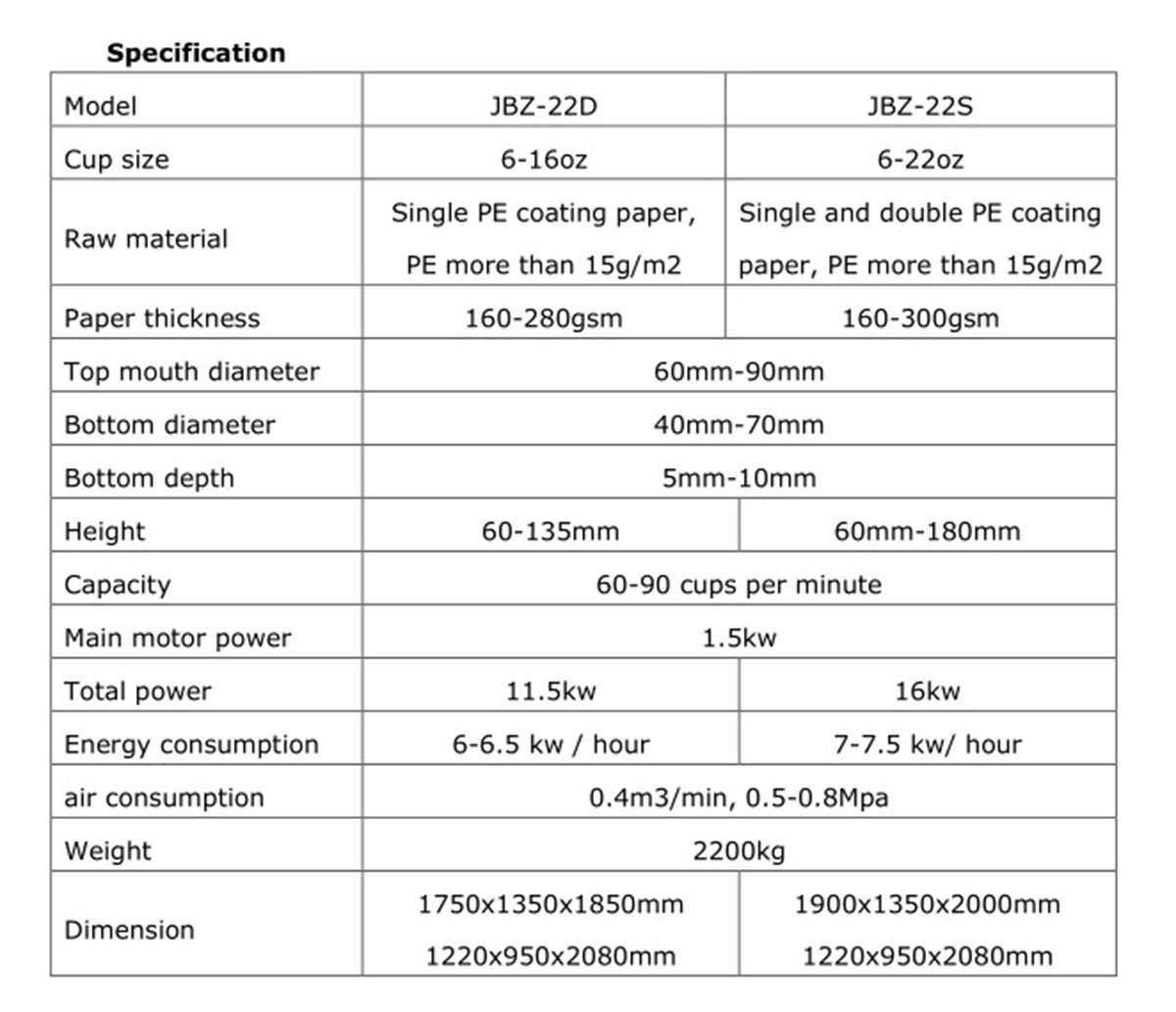

Specification

|

Model |

JBZ-22D |

JBZ-22S |

|

|

Cup size |

6oz-22oz |

||

|

Raw material |

Single PE coating paper |

Single and double PE coating paper |

|

|

Paper thickness |

160-280gsm |

160-300gsm |

|

|

Top mouth diameter |

60mm-90mm |

||

|

Bottom diameter |

40mm-70mm |

||

|

Bottom depth |

5mm-10mm |

||

|

Height |

60mm-180mm |

||

|

Capacity |

60-90 cups per minute |

||

|

Main motor power |

1.5kw |

||

|

Total power |

11.5kw |

16kw |

|

|

Energy consumption |

6-6.5 kw / hour |

7-7.5 kw/ hour |

|

|

Air Consumption |

0.4m3/min, 0.5-0.8Mpa |

||

|

Weight |

2200kg |

||

|

Dimension |

1750x1350x1850mm 1220x950x2080mm |

1900x1350x2000mm 1220x950x2080mm |

|

Product

Hot Tags: plc control paper cup machine, China plc control paper cup machine manufacturers, suppliers, factory