Our advanced paper cup machine is capable of producing a wide range of paper cups with high automation. Whether you need single side PE coated paper cups or two-side film-coated paper cups, this machine can meet your requirements. With its exceptional quality, the cups produced are suitable for both hot and cold beverages such as coffee, tea, soft drinks, and more.

The ultrasonic sealing system incorporated into the machine ensures a strong welding effect while using minimal energy, resulting in efficient production. Boasting a multi-working station, it can carry out all the necessary steps to create the cups, including automatic paper feeding, ultrasonic welding, handle processing, bottom punching, heating, knurling, curling, and cup discharge.

Overall, our paper cup machine is an all-in-one solution designed to meet your cup production needs with ease.

Main Characteristics

Placing the machine, the cut paper cup fans and cup handles will be arranged for efficient utilization. The focus remains on the original text information, ensuring a highly similar content is generated while rearranging the sentence structure.

The automated alarming system is equipped with a multitude of inspection points that regularly assess for any issues. Once a problem is detected, an immediate alarm is triggered.

The stable running is ensured by a robust gearbox and chain transmission system that is strong, firm, and precise.

To achieve a stable operation, a combination of two high-quality springs and three sturdy shafts is utilized.

In order to ensure the safety of the paper cup production process, the machine is equipped with a high-position stopping device. This device enables the machine to always stop at the highest point, effectively preventing any potential damage to the mold and the paper cup itself. Moreover, the heating furnace used in the production is completely separated from the mold, ensuring that the paper cup is not exposed to direct heat and eliminating the risk of it getting burned. This innovative design greatly enhances the overall quality and safety of the paper cup manufacturing process.

To ensure uniform bottom wrinkles, good sealing, and minimal leakage during cup forming, the use of a retractable knife is recommended. By incorporating this tool into the process, the cup's bottom can be formed with consistent wrinkles, ensuring a secure seal and reducing the risk of any potential leaks.

Based on the original content, the bottom rolling device, which is patented, offers an exceptional embossing force that is five times greater than that of a conventional rolling device. Let's generate a highly similar content by rearranging the information provided earlier:

With its patented design, the bottom rolling device surpasses traditional rolling devices by delivering an extraordinary embossing force that is five times more powerful.

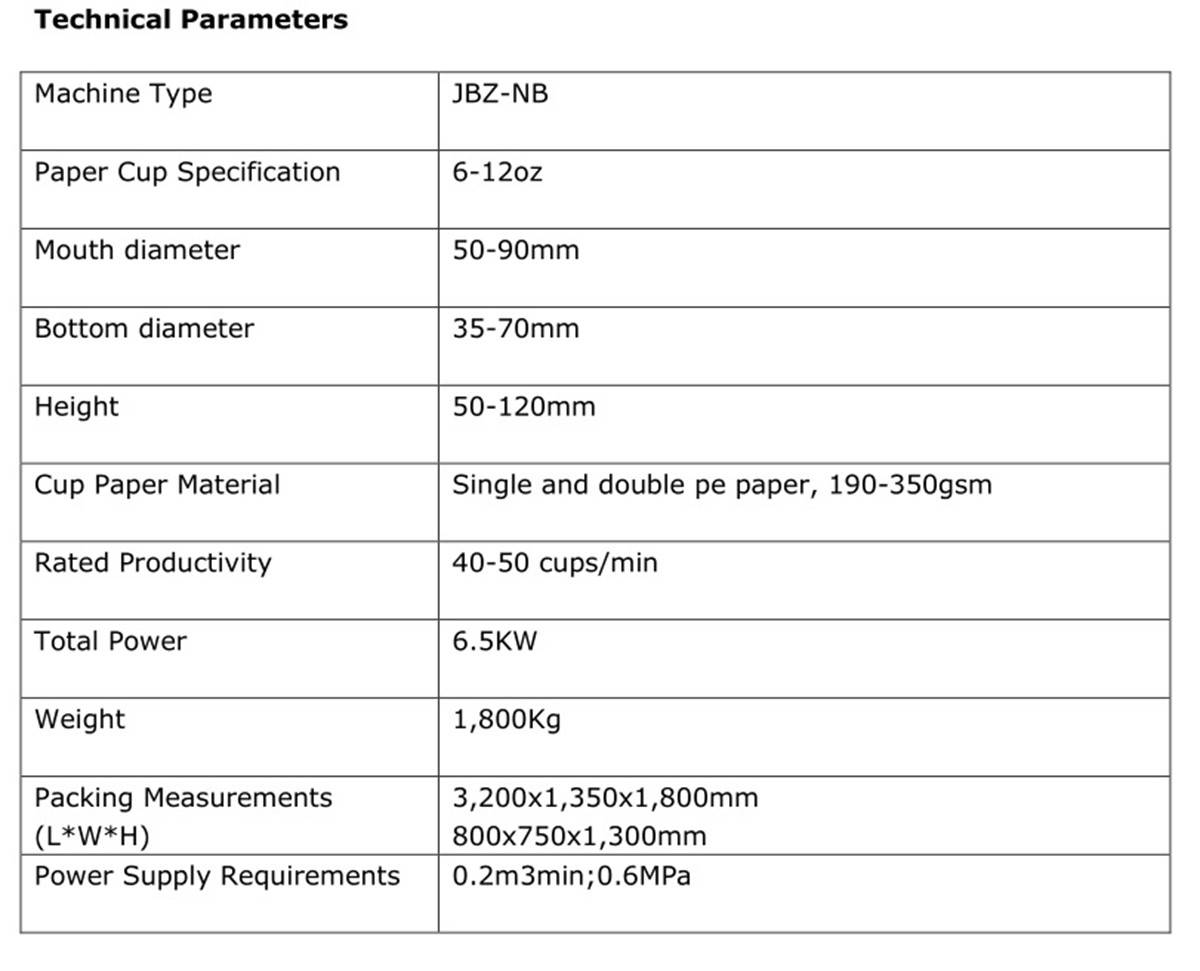

Technical Parameters

|

Machine Type |

JBZ-NB |

|

Paper Cup Specification |

6 ounces 8 ounces 12 ounces |

|

Cup Paper Material |

double-faced PE coated paper |

|

Cup Height |

50-120mm |

|

Rated Productivity |

40-50 pieces/minute (pcs/min) |

|

Power |

380V 50Hz(it can be changed if customer require) |

|

Total Power |

6.5KW |

|

Weight |

1,800Kg |

|

Packing Measurements (L*W*H) |

3,200*1,350*1,800mm |

|

Power Supply Requirements |

0.2m3min;0.6MPa (chosen by the customer |

Sini is a China paper cup machine manufacturer and supplier. We offer paper cup machine, and paper cup forming machine, paper meal box forming machine, paper cake case forming machine, paper cup sleeve machine. Our high quality products are offered at competitive prices. Sini is located in China, and the full chain of manufacturing die cutting machine, paper bowl machine can be completed in China, even in one city. Lower manufacturing cost saves your purchasing cost. The more details of each product are shown on the page with description.

Product

Hot Tags: paper cup with handle machine, China paper cup with handle machine manufacturers, suppliers, factory