The use of paper cups has become ubiquitous in various settings such as coffee shops, restaurants, and events. This soaring demand has made paper cup machines a vital tool for manufacturers. Paper cup machines are automated devices that expertly produce paper cups of different shapes and sizes with ease.

Working Procedure

The initial step of a typical paper cup machine involves the introduction of a paper roll into the machine through a feeding system. Subsequently, the paper roll progresses to the printing unit where the cup's design and branding are imprinted. After the printing process, the cup is advanced to the punching system where it is shaped and resized according to specifications. Finally, the bottom of the cup is securely sealed. This series of steps ensures efficient production of paper cups with consistent quality and desired features.

Features

One can find several notable features in the paper cup machine that ensure the manufacturing process of paper cups is efficient and safe. Its efficiency and safety are enhanced through the incorporation of different functionalities.

When it comes to designing and production, precision and accuracy play a crucial role. It is important to maintain precise measurements and calculations throughout the process to ensure a high level of quality. Precision refers to the level of detail and accuracy in the design and production process. It involves careful planning, meticulous measurements, and accurate calculations to create a product that meets the desired specifications. On the other hand, accuracy refers to the degree of conformity between the actual output and the desired output. In other words, it determines how closely the end product matches the intended design. Both precision and accuracy are essential in achieving a successful and efficient design and production process. Without them, there may be variations, errors, and inconsistencies that can compromise the quality and functionality of the final product. Therefore, it is necessary to place a strong emphasis on precision and accuracy to ensure the highest possible standards in designing and production.

2. User-friendly controls for easy operation

3. High-speed production capacity

4. Efficient paper usage for cost reduction

5. Minimal waste production

6. Automated counting and stacking system

Applications

There are diverse industries that make use of paper cups, and in these industries, paper cup machines find various applications.

1. Food and beverage industry

2. Hospitality sector

3. Event management companies

4. Office supplies and stationery shops

5. Manufacturers of paper and packaging materials.

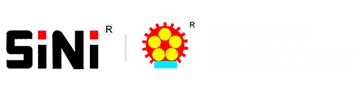

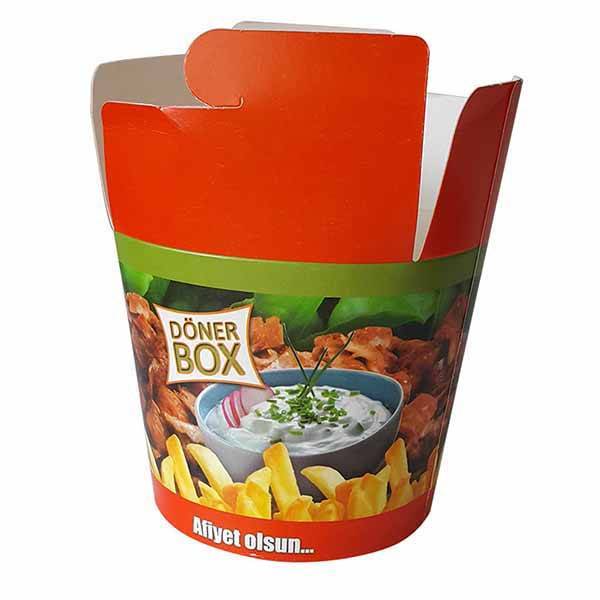

Product

Hot Tags: doner box machine, China doner box machine manufacturers, suppliers, factory