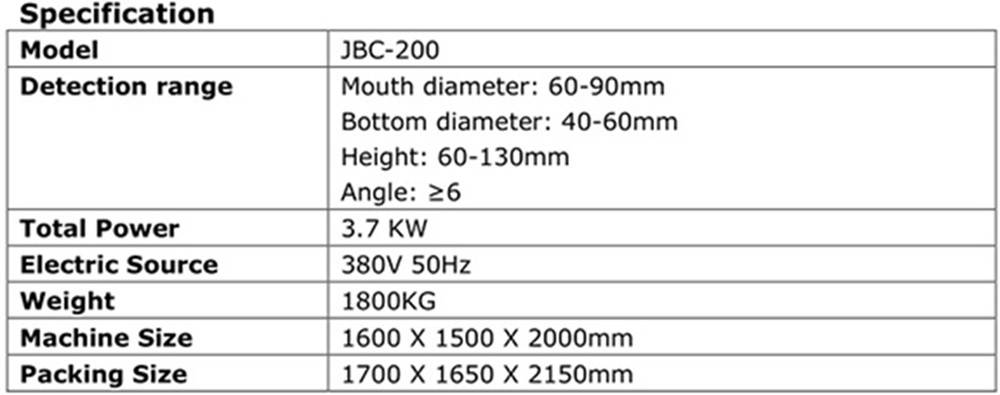

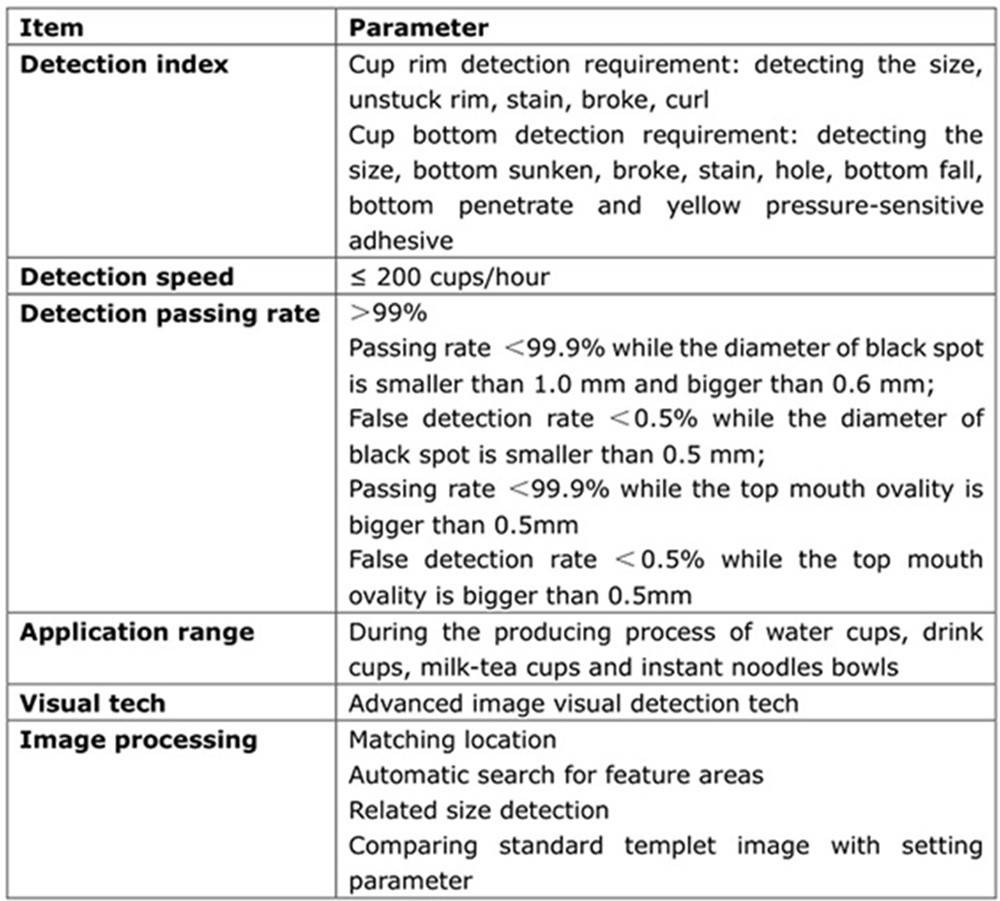

The amazing invention of the paper cup defect inspection machine is revolutionizing the paper cup industry. With a maximum operating speed of 200 cups per minute, this machine is boosting productivity and streamlining efficiency. Its state-of-the-art technology allows it to detect various paper cup quality defects such as dirt, size, and damage. This means that manufacturers and consumers alike can enjoy better quality products, as faulty cups can be identified and removed from the production line. Overall, this machine is a game-changer for the industry, providing automated and accurate quality control measures that benefit everyone involved.

The paper cup defect inspection machine offers a significant advantage by providing assurance of the quality of produced paper cups. With its quick and efficient detection capabilities, the machine ensures that any cups that fail to meet industry standards, such as those containing foreign particles, being incorrect in size, or showing deformities, are promptly identified. As a result, this prevents the entry of substandard cups into the market, safeguarding the reputation of the manufacturer.

The paper cup defect inspection machine offers another advantage, which is the potential for reducing labor expenses. By implementing this machine, the need for manual cup inspection is greatly diminished, resulting in a decreased demand for personnel involved in the inspection process. Consequently, not only does this machine save time, but it also significantly reduces production costs.

The paper cup defect inspection machine is notable for its efficiency and energy conservation features. It excels in precision, effortlessly detecting defects with utmost accuracy. By harnessing advanced technology, the machine eliminates the need for human intervention, ensuring a reliable sorting process for faulty cups. Additionally, its design prioritizes energy efficiency, resulting in minimal power consumption and reduced operational costs.

The paper cup defect inspection machine is an ingenious innovation that has transformed the way paper cups are manufactured. Its high-speed inspection capabilities, coupled with accurate defect detection, have become a crucial component of the manufacturing process. This machine's advantages, such as ensuring top-quality paper cups, reducing labor costs, and promoting energy conservation, make it an indispensable asset for any paper cup manufacturer looking to stay competitive.

To sum up, the paper cup defect inspection machine has revolutionized the paper cup industry and has become an essential asset for its manufacturers. Its ability to quickly identify defects in a highly efficient manner ensures that manufacturers produce only the highest quality paper cups. Moreover, implementing this cutting-edge technology also minimizes labor costs and promotes eco-friendliness. Overall, the paper cup defect inspection machine is a true game-changer that is here to stay.

Product

Hot Tags: paper cup detection machine, China paper cup detection machine manufacturers, suppliers, factory