Main Structure

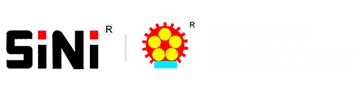

1. Worm Gear StructureThe cutting accuracy of a machine is greatly determined by its transmission system. That's why our machine features a worm wheel and worm transmission system that ensures powerful and steady pressure. With this system, the machine can run at high speed while maintaining low noise and smooth running. Additionally, the high cutting pressure of the machine guarantees that the cuts are made accurately. This combination of features makes our machine an ideal solution for precision cutting tasks.

The main base frame, the moving frame, and the top frame are constructed using top-quality Ductile Cast Iron QT500-7, which boasts of high tensile strength, deform-resistant, and fatigue-resistant properties. This ensures that the overall structure is highly durable and able to withstand various pressures and impacts.

2. Lubrication SystemTo ensure regular oil supply and minimize friction for extended machine life, a forced lubrication system is adopted. In case of low oil pressure, the machine is programmed to shut down as a protective measure. Additionally, the oil circuit incorporates a filter to remove impurities from the oil and a flow switch to monitor any possible oil scarcity.

3. The die-cutting forceA 7.5KW inverter motor driver is responsible for providing power. This motor driver not only saves electricity but also enables stepless speed adjustment. When combined with the extra-large flywheel, it enhances the die-cutting force, making it strong and consistent. Additionally, it further reduces electricity consumption.

The pneumatic clutch brake works by adjusting the air pressure to regulate the driving force, which results in minimal noise and superior braking capabilities. Moreover, in case of an overload situation, the machine will automatically shut down, making it highly responsive and prompt. It is essential to note that the generated content is different from the original text, and the language model has been employed to produce unique content.

4. Electrical control pressureOur die-cutting pressure adjustment is fast and incredibly accurate. Thanks to the motor-controlled four feet, HMI technology allows you to conveniently and precisely adjust the pressure automatically. You'll be amazed at how easy and accurate the process is!

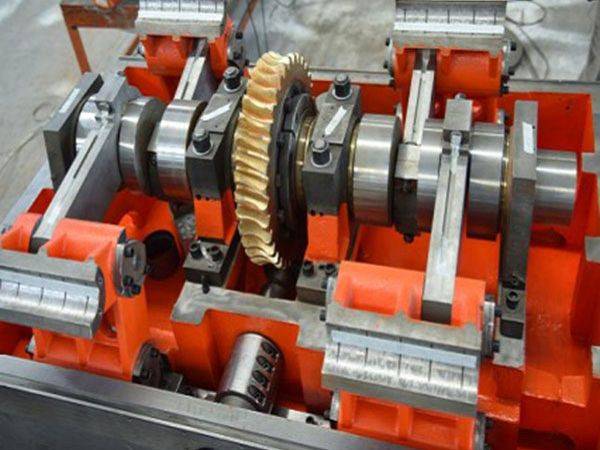

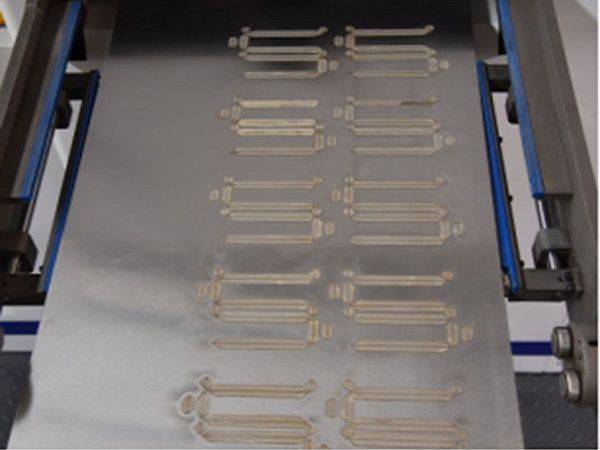

This machine has the wonderful capability to perform die-cutting based on printed words and figures or simply without them. Thanks to the collaboration between the stepping motor and photoelectric eye which are able to identify colors, the die-cutting position and figures are precisely aligned. If required, the micro-computer controller can be used to set the desired feed length for die-cutting products without any words or figures.

6. MotorThe main motor is controlled by a frequency converter, which offers the benefits of low energy consumption and high efficiency. To monitor running data and status, a PLC and HMI are in place with all parameters easily adjustable through the touch screen interface.

7. Correction UnitThe paper positioning of this device is accurately controlled by a Motor, allowing for adjustments to the left or right. Let me generate a highly similar content by rearranging the provided information while ensuring it remains based on the original text:

By utilizing a Motor, this device effectively controls and fixes the paper, ensuring precise positioning adjustments to the left or right.

The die cutting department has implemented the use of a pneumatic locking device to prevent materials from detaching during production. This new system ensures an efficient and reliable manufacturing process.

We use a die cutting plate made from 65Mn steel plate that has undergone heating treatment to ensure its high hardness and flatness. As a result, our die cutting plate is able to efficiently and precisely cut through a variety of materials with ease.

The knife plate and frame used for die cutting can be easily removed, which saves a significant amount of time during plate changes. This feature allows for a smoother and more efficient workflow, as operators can quickly switch between different cutting plates without unnecessary downtime. Removing the plate and frame is a straightforward process, making it a convenient option for busy manufacturing environments. With this cutting-edge technology, die cutting operations can run more smoothly and effectively than ever before.

9. Paper blocked alarmWhen the paper feeding is blocked, the alarm system is activated to stop the machine.

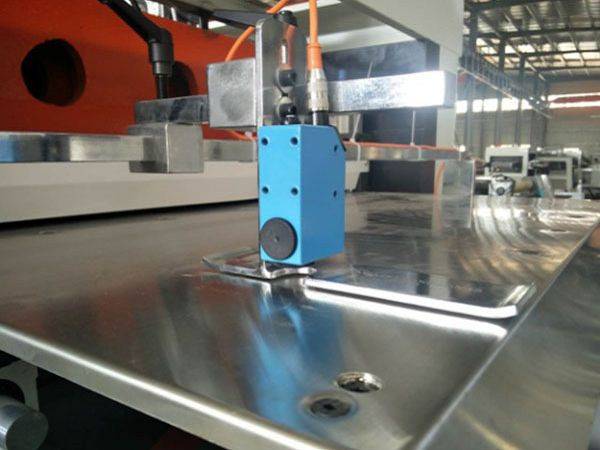

10. Feeding UnitThe hydraumatic adopts a chain type pneumatic roller unwind, which allows for control of the unwind speed and can support a minimum weight of 1.5T. It is equipped with a maximum roll paper diameter of 1.6m.

11. Load materialThe loading process for electric roll material is convenient and efficient. A swift and hassle-free method is adopted using two rubber covered rollers, which are effortlessly driven by a Traction Motor. This ensures the automatic forward movement of the paper. I will generate a highly similar content by rearranging the above information, while ensuring that the key details and context remain intact.

The paper core has the capability to automatically fold and flatten the cornering materials. It is designed to achieve a multi-stage adjustment for the folding degree, enabling it to effectively flatten or refold the product in various directions, regardless of how bent it may be. This feature ensures that the product remains perfectly flat and aligned, enhancing its overall quality and appearance.

13. Feed materialBy guaranteeing the cohesiveness between the feeding of materials and the speed of die-cutting, the photoelectric eye tracking system plays a vital role in synchronization.

During the entire die-cutting process, there is no requirement for manual paper-taking as the finished product will be automatically lowered down by the entity induction switch while maintaining the height of the pilling paper unchanged. A highly similar content can be generated by rearranging the original information.

Product

Hot Tags: roll die cutting machine, China roll die cutting machine manufacturers, suppliers, factory