Thermoforming machines for plastic have introduced a revolutionary technology in the manufacturing industry. This advanced process involves heating plastic sheets and shaping them into various sizes and forms. With several advantages over traditional manufacturing methods, these machines are transforming the industry.

One of the primary benefits of utilizing a plastic thermoforming machine is its high level of efficiency. When compared to other molding techniques, this process is remarkably quick and streamlined. The equipment has the capacity to handle significant volumes of plastic in a short time frame, which significantly boosts manufacturers' output. This leads to more efficient manufacturing processes, shorter production times, reduced costs, and increased customer satisfaction. Ultimately, utilizing a plastic thermoforming machine enables companies to improve their operations and enhance overall profitability.

One major advantage of utilizing a plastic thermoforming machine is its exceptional efficiency. This advanced technology enables the production of top-notch products while minimizing waste. The process itself is highly automated, requiring minimal manual intervention, thereby decreasing the likelihood of errors and enhancing quality control mechanisms. Moreover, this technique delivers a greater material yield, ultimately reducing the costs associated with raw materials.

Plastic thermoforming machines offer several benefits to manufacturers, one of which is the ability to reduce labor costs significantly. Since the machines require minimal manual labor, fewer workers are needed to operate them. This can lead to considerable savings, especially in regions where labor is expensive.

The reduction in labor costs provided by plastic thermoforming machines can help manufacturers stay competitive in the global market. With lower production costs, they can offer their products at a more competitive price and attract more customers. This, in turn, can lead to increased revenue and profitability.

Moreover, the use of these machines also improves the quality and consistency of the products produced, reducing waste and enhancing productivity. By automating the manufacturing process, manufacturers can ensure that their products are of high quality and meet consistently high standards.

The benefits of plastic thermoforming machines are clear, and manufacturers worldwide are continuously investing in automation to stay competitive. By reducing labor costs, improving quality and productivity, and offering products at more competitive prices, manufacturers can achieve their goals of increasing revenue and profitability.

The plastic thermoforming machine is a highly versatile technology that finds its utility in a wide range of industries. From producing packaging materials and medical devices to automotive parts and consumer goods, it is suitable for several applications. The flexibility of this technology makes it a popular choice for manufacturers, regardless of their industry. Therefore, it is a reliable and preferred option for producing a range of products seamlessly.

Plastic thermoforming machines have revolutionized manufacturing processes in several ways. With their capability to produce high-quality products in a fast and efficient manner, they have quickly become a preferred choice for many manufacturers. By minimizing manual labor requirements, these machines save both time and costs.

Thanks to their high level of versatility, plastic thermoforming machines can be used in a wide variety of applications, making them a very useful asset to have for any manufacturer. Their ability to produce precise molds of any shape with ease, along with their quick production turnovers, means that manufacturers who use these machines can expect improvements in productivity, efficiency, and profitability.

In conclusion, the use of plastic thermoforming machines has a significant impact on manufacturing operations, offering several key benefits that can help businesses grow and thrive. The technology is fast, efficient, and requires minimal human intervention, making it a clear advantage over traditional manufacturing processes. The flexibility and versatility of these machines, coupled with their precision and accuracy, make them a highly valued tool in today's manufacturing industry.

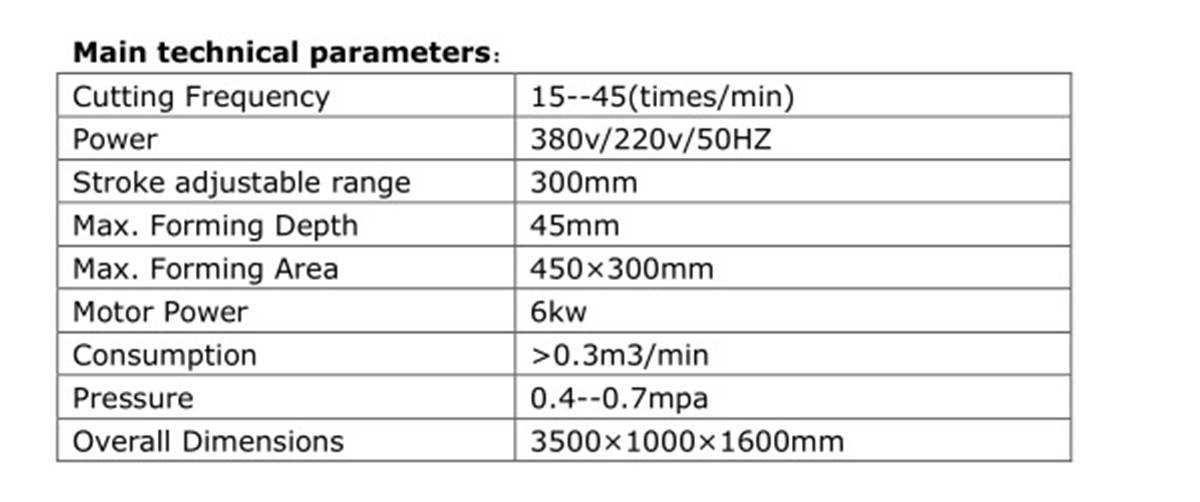

Product

Hot Tags: plastic lid forming machine, China plastic lid forming machine manufacturers, suppliers, factory